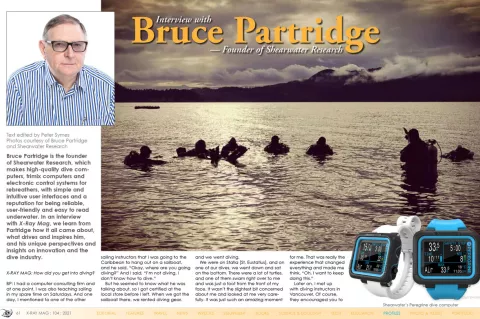

Bruce Partridge is the founder of Shearwater Research, which makes high-quality dive computers, trimix computers and electronic control systems for rebreathers, with simple and intuitive user interfaces and a reputation for being reliable, user-friendly and easy to read underwater. In an interview with X-Ray Mag, we learn from Partridge how it all came about, what drives and inspires him, and his unique perspectives and insights on innovation and the dive industry.

Contributed by

X-RAY MAG: How did you get into diving?

BP: I had a computer consulting firm and at one point. I was also teaching sailing in my spare time on Saturdays. And one day, I mentioned to one of the other sailing instructors that I was going to the Caribbean to hang out on a sailboat, and he said, “Okay, where are you going diving?” And I said, “I’m not diving, I don’t know how to dive.”

But he seemed to know what he was talking about, so I got certified at the local store before I left. When we got the sailboat there, we rented diving gear, and we went diving.

We were on Statia [St. Eustatius], and on one of our dives, we went down and sat on the bottom. There were a lot of turtles, and one of them swam right over to me and was just a foot from the front of my face. It wasn’t the slightest bit concerned about me and looked at me very carefully. It was just such an amazing moment for me. That was really the experience that changed everything and made me think, “Oh, I want to keep doing this.”

Later on, I met up with diving instructors in Vancouver. Of course, they encouraged you to continue to take classes so you could give them more money. I just kept taking classes. I was retired at the time, after having sold a consulting company, so I did have the time to do it.

I ended up diving more, taking more courses, and eventually also technical diving courses. Back then, it was pretty much on rebreathers that really weren’t rebreathers. The military could use them, but it wasn’t a recreational thing. But I kept on taking courses.

Meeting my wife

Next, I was going out on a liveaboard in the Vancouver area in cold water and drysuits. On one day, this lovely woman stepped onboard with her low-pressure 85 twins on her back. That was Lynn, and we did not hit it off well. At the time—you know, I’m not going to go into any details—she wasn’t instantly attracted to me, and when I found out that her boyfriend climbed on afterwards, I was sort of less interested as well.

But as time went on, we dived together; we would see each other on dive boats, and she was a technical diver as well. Then at some point, years later, she had broken up with her boyfriend and we met at a dive show and decided to go out on a date—and the rest is history. We ended up getting married and living together. At that time, I was still retired, but the money was running low. I didn’t have enough to stay retired for the rest of my life, so I had to do something.

Unhappy with existing devices

I don’t want to offend anyone, but I was quite unhappy with what was available on the market. Having been in the computer business my whole life, I had spent a lot of time thinking about user interfaces and intelligent interactions between devices and people. So, I thought that what was on the market was quite lame and had very odd interfaces. The one computer I was thinking about had symbols for what you wanted to do and, in theory, that’s a good idea. But I don’t know how you make the mental leap associating a picture of a wrench with changing gases. I can do better than this, I thought. So, I decided to make my first computer.

I was diving rebreathers, so my first computer had to work with rebreathers. Because my contact with the industry was through the Rebreather List and Rebreather World, which was the big forum back at that time, we were part of a very international community, with like seven rebreather divers in each country, or something like that.

My first three sales went to Saudi Arabia, California and the UK. That was sort of how scattered it was. So, we started off being international from day one. There was never any question about it being a Vancouver business.

Analogue sensor

Anyway, so that’s what got started. It turned out to be not a very good computer. I was using an analogue depth sensor, which would need to be recalibrated once a year. And there’s just no practical way to have people shipping computers back from all over the world every year to have them calibrated.

So, I bought those three back, and I said, “Guys, give me a year, and I’ll have something else.” This led to the second version, which was much more professionally done and used a digital depth sensor.

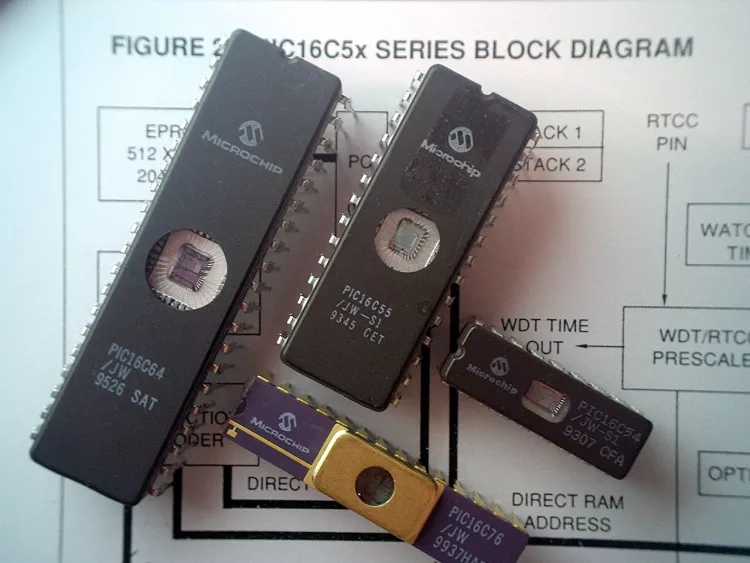

I wrote all the software, the firmware, for the product. That little part was a one-man show, and when I got to be pretty happy with it, I contracted an electrical engineer to do a board layout for me. I did all my own circuits too. I wasn’t the hardware guy, but I learned how to use op amps [ed. operational amplifiers], how to use memory chips, how to mount a microprocessor and how to put power to it—and that sort of thing. I figured all that stuff out.

PIClist

A lot of what I got came from something called the PIClist [ed. the PICList is a collection of people interested in the Microchip PIC and other similar processors who have joined the PICList]. PIC is an entry-level, controller-type computer and a very simple device. You might put one of these in a lamp, telephone or flashlight, but they’re not meant to be sophisticated, run word-processing or anything like that; they’re quite simple processors.

The PIClist had thousands of people on it and many whose hobby it was to help others. You would send a question out, and somebody would send back a three-page answer with links to references and explanations on a really simple level. You could ask questions like what is an op amp? How do you connect it? Why do you use it? Should it be bi-directional or uni-directional, etc? Using that information, I built a breadboard, and this is only the digital side. One of take-aways of all this is that we would probably not have existed if it were not for the internet.

I didn’t know anything about how to do the analogue side, so when I was ready to do the board, I called up one of the engineers on the PICList. We had a meeting at a restaurant, and he said he’d be happy to do it.

I brought mine in and he refrained from laughing. It was all these wires going from one pin to another on a breadboard. It was quite a mess. We talked about it, how bad it was, later. But it worked. So, he did the board layout for me, had it sent out to a board manufacturer and got it back. He was a consultant back then, but that guy still works for me.

I now had my circuit board. Next, I needed a case. At that time, KISS was in Vancouver, and they had their handsets, boxes and containers made by a machine shop in town. They were happy to make cases for our first computer—the GF, which was a monochrome computer but fully trimix-capable—and we made that [model] for a while.

The next one was the Pursuit, which was quite a clean-up [on the previous model]. It still had a monochrome display, but instead of just being a block, the case actually had some shape to it and looked a little bit better. It was also quite a bit smaller, because a lot of effort went into miniaturizing after the GF, which was a bit of a brick.

At that point, it was starting to become a business. So, we rented a bit of space in an office building and hired one full-time guy. I also had a part-time accountant. For many years, we had a list of every one of our customers and the serial number of their units, because we were still selling only direct.

Because of this whole enabling of the internet, I was sitting in an office in Vancouver, and I was communicating with people all over the world through the Rebreather List and Rebreather World. There were a lot of esoteric and interesting people on the Rebreather List. Fascinating stuff, but all that is all gone now, I think.

It eventually became too much for me to do the sales, be on the phone, do the shipping all around, and build all the computers—or assemble them [rather], because a board house would build a circuit board and the machine shop would build the case.

I went to a contract manufacturer, so I could just send them the parts. Then they would make five or ten of these things and pick them up. Then I would bring them back to my office, package them in a UPS bag, and the courier would come to the office and pick them up. That was the company, which was basically me, full time, and a couple of part-time to full-time employees.

Growth

Lynn and I then decided to share a bigger office, and at that point, I hired a full-time engineer. This was also when we first built the Windows interface so that you could update firmware from a Windows program.

We kept growing, so we decided to move to an industrial building. Then we took over the bay next door and doubled our space again and continued on. But still, we only had probably less than 10 employees at that point. We then hired Tyler, an engineer, and he was so good. He really upped the game for our company, and now our products were much more professional and sophisticated. We continued to just grow, and the products got more sophisticated and more interesting.

X-RAY MAG: Prior to all of this, did you know anything about running businesses? Or did you just learn on the fly? And did you have any bumps along the way, in that learning curve, that you can reflect upon in hindsight?

BP: I was pretty much already in business. I took a year of commerce and did my first year [at college], where I specialized in computing science. I did really well, and in the end, I was making so much money, there’s no way I could go back to school. I then went to a consulting company, which was doing timesharing, and they had about 70 customers around the city.

Access to mini-computer

I worked there for several years, and of course, learned a lot. It had a radio school, and a mini computer. It was fascinating in the sense that I had access to the computers that you would just never get nowadays. As a junior programmer, I could walk into the computer room, turn things on, unplug things and plug things in. No programmer would get that kind of access nowadays. But I was in there and I learned a lot.

I then ended up getting into Gandalf data communications. That company’s long gone, but it was a rock star back in the day, making communication systems for companies. I was the branch manager. When it started, it was just me, so I was the branch. But I ended up with bigger industrial clients and schools. That was sort of my beginning in business.

X-RAY MAG: Maybe I can try to turn the question a little bit on its head. Because I think there are many companies, in particular start-ups, where the founder is the innovator, the visionary, who in many cases, has little or no prior knowledge about being a managing director. Do you have a piece of advice for upcoming start-ups in the diving industry? How do you manage growth and make that transition, or combine being an inventor, or visionary, and a managing director?

BP: Well, I’m sorry, I can’t be very helpful. I was born to a father who worked for a multinational company where he was a a national manager. So, I have had business-level conversations my whole life. It was what we talked about in the house. But that’s just one side of it.

The other side of it is—and this is key to our success—if you don’t know what you’re doing, hire somebody or rent somebody who does. And that has been our policy from the beginning. We didn’t try to do stuff that we didn’t know how to do. If I don’t know how to do something properly—if, say, it is board layouts—I can hire an engineer and get somebody who does know how to do it. We [followed that strategy] to the extent that we now have a completely professional management team. I don’t have to do anything anymore. This company is completely self-sufficient [in regard to its] management. It’s taken a few years to get there [though]. But yes, I had a lot of exposure to business, and I got good advice, which helped me get going.

X-RAY MAG: Is that also why you hired a CEO? Was it a matter of finding better competence in that area, or did you want to enjoy a little bit more free time?

BP: It’s actually both. That said, I was pretty good at being a manager. A lot of being a manager is just being a good person, listening to your employees and treating them with respect. Management comes fairly easily if you just start with these kinds of principles.

But yes, absolutely, the reason we hired a CEO was because I had outreached my ability to run this company. Up to a certain point, when you can talk to everybody and you can get pulled in a room and just have a conversation, that’s one thing. But when we got to [the point where we had] people working in different cities and chains of command in engineering, sales and production, that was way beyond my skill set.

At first, I brought in managers below me, again, for engineering, choosing engineering and sales [personnel], and Lynn was the sales manager. Then I got to a point where even that was getting too sophisticated, so I hired a guy who was used to running a multinational [company], and he is still our CEO.

At some point, the company did outgrow me. Could I have learned how to do it? Maybe. Did I want to? No.

X-RAY MAG: Where does your inspiration come from? Do you have any role models? How do ideas come to you for new products or functions? You mentioned in the beginning that you questioned why somebody would use a wrench as an icon for a function on a computer and that this spurred you to create your first computer. So, are your ideas a reaction or response to something you don’t feel is working well. Or do you have sort of “eureka” moment or vision where an idea comes to you? Is innovation an incremental and evolutionary process or does it spring from moments of inspiration?

BP: I think it is a mix. If you look back at our product history, starting with the GF [model]—this brick with a monochrome screen that weighed about six pounds—and on to where we are now, it is clearly a stepwise refinement, which really took off when I had professional engineers working for me. And that goes back to one of my principles about reaching out and hiring that next guy you need—maybe before you can quite afford him—to take you to the next level. In that manner, we have always tried to stay ahead. But, yeah, it’s very definitely a stepwise refinement.

But another really important factor is that we’re all diving these things, including the engineers. So, it’s not like they’re in some closed office, not having anything to do with diving. Everybody who comes to Shearwater gets a free dive certification. We rent equipment for them, and we pay for their courses. A huge proportion—even of our people in production and in accounting—they all learn to dive.

X-RAY MAG: You mentioned hiring the right people, finding the right people and having a good rapport with your associate collaborators or employees. How big of a role does the team and the team dynamics play in innovation?

BP: I think it plays a huge amount. We have a great company; everybody says that. If you go into our company, and you walk down the halls, people are laughing, and they’re having fun, and they’re friends. They socialize together sometimes; we have regular events.

There’s no concept of the new hire production manager not being able to go and talk to a manager whenever he feels like it. We just try to be a really strong team. One of our four prime thoughts that keeps the company going is you have to treat everyone with respect. If you don’t treat people with respect, you can’t work for us. So, there’s absolutely no problem with people’s production, or people going to talk to anybody or any of the managers in the company.

The other side of it is treating customers with respect. And it’s surprising how much spirit you can get when people feel good about doing their jobs—that they’re making people happy, that you get customers emailing you back and saying, “Wow, thanks. Nobody’s ever done that for us before.” And it really builds the spirit of the company.

X-RAY MAG: So, you teach newcomers that they are valuable from the get-go, and they shouldn’t be afraid of speaking up, even against people who have seniority?

BP: Yep, exactly.

X-RAY MAG: Is that an active step that you take? Do you explain to them or teach them company culture? Or is it just implied by the way you converse on the job and arrange your workflows?

BP: It’s somewhat organic, because we started off thinking [this way] but didn’t formalize it until we moved to our third [and] last building, at which point, we were probably only 20 or 30 employees. I was getting beyond my skills in manufacturing, so I brought in a general manager who was very, very good at manufacturing and did wonders for organizing production. She also wanted to codify things and made us think about our values, and the need for putting them into words. You know, it can’t be just ad hoc, what our values are. She was the one who coached us into getting our values, and what we believe, written down. We put them up on the wall in all the common areas and live by them.

Treating people with respect means that managers have to be aware of how people are reacting to their behaviour. And when we say treat everyone with respect, that includes customers. So, even if somebody’s being a little bit difficult, we try really hard to treat them with respect.

X-RAY MAG: Where do you see the current frontier in the development of dive computers today? And where do you believe it will be in 5-10 years? What do you think will become possible? And in which areas do you think the next developments will take place? Or what do you think needs to be invented next?

BP: Yeah, that’s an interesting question—And kind of hard to answer.

In terms of our products, of dive computers, we’re pretty much technology-driven. It is the same, whether you’re looking at a computer keyboard or a screen or, for that matter, even a light on our furnace, we move with technology.

Key technologies

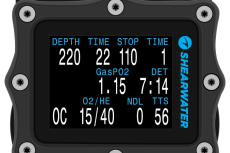

The two key technologies in regard to any handheld device, whether you’re talking about a telephone or a dive computer, are displays and batteries. And the driver of development in these two areas is the phone business. As these technologies continue to improve, they drive a lot of the things that we can do.

In the early days, there weren’t any good end-user displays. So, we were almost always stuck with industrial displays such as displays of CNC milling machines, because that’s just all there was. There wasn’t much of a concept of handheld displays until phones took off more. My first mobile phone weighed about 30 pounds and had a handle on it. You lifted the receiver off the battery, which was the size of a Kleenex box. So, in the beginning, we used industrial technology, and machine-tool type stuff was driving the processors and displays. Now, it is the phone business that’s driving the processors that go into so many types of devices, and every year, microprocessors get more powerful and use less power.

X-RAY MAG: Dive computers are essentially just calculators that simulate gas loading in tissues. Do you think that we will, someday in the foreseeable and not-very-distant future, get technology that will directly measure gas loading in our tissues, say, through the skin, through some advanced technology that could be built into a future dive computer, or some other dive instrument?

BP: Not in the sense of decompression, I don’t. The problem is [that] by the time you detect anything in decompression, a bubble in the blood, you’re already too far—you’re already caught by it, right? Although there may be some bubbling that happens to be safe bubbling—and I think there will be, as there is always a little bit of bubbling going on—I’m not aware of anything, even in the future, that will change that.

The thing that I believe will change is other body sensing. In the space program, there has been interesting work going on for decades. They’re monitoring people in the space program in many ways; they can tell when [the astronauts are] asleep, when they’re awake, what their heart rate is—all that sort of stuff. And I think as time goes by, we’ll see more of that with dive computers. Or perhaps not dive computers as such, as it might be something more akin to what is on rebreathers.

On that note, I wouldn’t be one bit surprised if 10 years from now, open circuit is very unusual and entry-level rebreathers has become the norm. There are just so many advantages to them. I’m a big believer in recreational rebreathers, even though our company does not have any particular footprint in this field.

When I first started to dive, I wasn’t particularly fit, and I was diving with a wetsuit and lots of weight in cold water. I would get 15 minutes off the tank. That was discouraging, and I’m not sure why I kept at it. I was around 40, and seeing how an 18-year-old could just pick it up in a snap, have a low breathing rate, and be able to last half an hour longer than me, was quite discouraging.

Now, when I look at it, and you ask how we can continue to grow the dive industry, I think of semi-closed rebreathers. Closed circuit is too complicated. It is too easy to kill yourself with it, frankly. My vision is a semi-closed rebreather that is much more forgiving in terms of making sure you have a gas that is breathable. Only, now you have a scenario where that new diver can last as long as he wants.

So, you’re on your open water class. And yes, you have to deal with this big drysuit and the weight and have to climb in and out of the boat. And you know, by the time I get into the water, I’m already panting. But it doesn’t matter, because you’re not going to run out of air, right? And we’re going to do a 40-minute dive, and everybody’s going to do a 40-minute dive, and everybody’s going to be able to do a 40-minute dive. I personally think that’s the future.

X-RAY MAG: You’re very particular about quietly supporting dive research. Where does this philanthropic ethos come from? What research have you supported? And how do you pick whom to support?

BP: We got into research by attending meetings. The first we attended was a meeting of the Undersea and Hyperbaric Medical Society (UHMS) in the [United States]. Dr Simon Mitchell was there talking about deep stops, and we thought since we’re making dive computers, we should attend. There we were, among some 80 to 100 attendees, all medical professionals in the field of hyperbaric medicine, except for us and a representative from a manufacturer in Europe.

Lack of consensus

We were floored by the lack of consensus. I guess one of the surprising things was that even amongst the medical community, there’s a lot of differing ideas. So, after Simon did his presentation, there were 20 people in line to ask questions and people calling in from the audience. It was very dynamic and and fascinating; we learned so much. So, we thought, “Oh, okay, this is kind of interesting.” And as computer manufacturers, we have a duty to stay on top of where hyperbaric medicine is, and that got us started with it.

Then we started moving into other undersea medicine groups and got very involved. We just got into the science of it. Obviously, a lot of these folks are avid divers as well, so we have sort of become part of the diving science community too. What keeps us interested is that we’re listening and talking to people on a regular basis, multiple times a year, who are presenting interesting, often conflicting ideas, on the whole idea of how decompression works, whether micro bubbles matter and all that sort of stuff.

One of the big things for us is watching the lack of agreement and the arguments on either side. That was how we really got into the science side of it and continue to participate.

Until recently, we went to two or three of these events a year. At the meeting in South Africa in which all the hyperbaric medicine organizations of the world participated, it was fascinating to listen to all the different opinions and different positions and bring this information back with us.

If there’s anything that we think we’re maybe not doing exactly the right [way] on our dive computer, we’ll come back and say, “Okay, you know, the consensus is that this is really not the best way to do things.”

X-RAY MAG: Why the bird names? Is it because you are a Partridge?

BP: Yes. Shearwaters are our pursuit predators, and the bird, and I dive. We continued to name all of our products after a bird—preferably, a species that has some relationship to diving.

X-RAY MAG: What did it mean for you to win the EuroTek award?

BP: It was great. It was also stressful to go up on the stage and be expected to say something when you are not used to public speaking. But obviously, it’s a great validation that we’re on the right path. And it’s wonderful to hear that other people think we’re doing a good job and think we’re contributing to the community.

X-RAY MAG: What do you personally get out of your dives?

BP: I do enjoy the life I encounter. I’ve done some wreck diving too, but at this point, I’m much more interested in life. I like looking at fish, particularly the sharks, and having seals playing hide-and-seek and intentionally interacting.

Dive community

The other aspect is that I love the community. There are so many interesting people on dive boats. The confluence of diving, diving science, animals and people is what makes the most fun come out of it. It’s created a whole community for us, and much of our travel and our recreation revolves around the people we dive with. It is an international camaraderie. You go to the dive shows around the world, meeting people, and all of a sudden, you have friends in Denmark, Canada, the US and in Australia. It is fascinating.

X-RAY MAG: How do you come up with the design and aesthetics of your computers? Is that left to designers?

BP: We have been lucky enough to have some really strong people, many of which have been with us for many years. Our engineering manager drives the design, and he is also so much better at it than I am, and he will show us stuff. We also have mechanical engineers who make physical presentations of the new products. My involvement in design is now restricted to product development meetings where the team will present a product and what they want to do with it. Usually, I love it, and sometimes, I also wonder why I didn’t think of the good idea myself.

But there are times—because I still know the diving business better than many of the engineers—when I’ll say I don’t think that’ll fly, or I think that feature is dangerous, and for these reasons, I don’t think we can put it in. But mostly, it’s just driven by the engineering department.

X-RAY MAG: I can’t help making a connection between this and what you mentioned in the beginning, about the wrench being a not-so-obvious symbol for something. Is usability or design aesthetics also part of your company values or profile?

BP: Absolutely, although it is not in our actual written values, and the ease of use of our products is also hugely important. The meetings where we have the most discussions, and where we really work on getting things right, is about the user interface, where we debate how various kinds of divers will react to some feature and how it would work for a guy that dives a rebreather and so on. That’s a huge part of the way we do things.

What also plays a big part is the fact that almost everyone in the engineering team is a diver. They may come back after a dive and say, “Well, that’s stupid—that doesn’t work. You know, I had to push the button three times, and then remember whether it was one or two. We can’t do that. It has to be simpler.” That is really where the designs are driven from, primarily from the engineering team, who are all divers.

X-RAY MAG: What software do you use? Is it of some models that you have developed yourself? How do you verify and validate your decompression model? Is it according to any kind of empirical data? Or do you use a standard theoretical model in your computers?

BP: Honestly, I don’t know. I am several levels away from that nowadays.

I don’t know if you are aware, [but] we were very involved in the International System Safety Society. I have an award here on my wall [from them that says]:

“International System Safety Society, Scientific Research, Research and Development Award 2013, presented to Shearwater Research, in recognition of outstanding development of system safety engineering methods.”

We take it seriously. It is not about what we feel like doing, but about what science says and what engineering says. What are the best practices in a nuclear reactor or a car, for example?

Let fails be obvious

That’s always been one of our priorities. I am really confident that we build safe systems, which fail in obvious ways if they fail, or don’t fail. We tried really hard not to make systems that fail in subtle ways. If they fail, let it be obvious. And we do get some flack over this. Not a lot, but once in a while, people will ask about why we won’t do some feature. Sometimes, we will respond that it is because it’s just too prone to allowing somebody to do it wrong, and the consequences could be quite serious.

It does not happen a lot, but I can think of a couple of times when we got a request for a feature, and we looked at it and analyzed it. We use formal safety system analysis and there have been instances when you think, “Geez, if he then pushes this button wrong, he’s going to die.” So, we don’t want to go there.

It is typically not about whether a diver is going to die but about being way off in regard to decompression and that sort of thing. So, sometimes the way you switch gases, and so on, could be made more streamlined, but we want to make really sure that the people understand what they’re doing and that they’re doing the right thing.

X-RAY MAG: Any concluding comments?

BP: I take a lot of pride in the fact that the company runs on its own now; it doesn’t need me. You know, I don’t go to the office anymore. I get emails from time to time, and I get invited to meetings from time [to time], particularly for doing a new product or something, and [how it] will sell. I just take a lot of pride in the fact that I’ve created a self-sustaining, self-sufficient, proud, happy company.

And that is quite an achievement and an accomplishment most people will never make. ■