Standard for testing the CO2 absorbent used in breathing equipment

BSI, the business standards company, has published BS 8618,Granular carbon dioxide (CO2) absorbent material for life support, diving, hyper- and hypobaric applications – Specification.

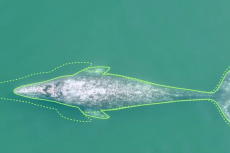

Divers use mixtures of oxygen and breathing gases during a dive. For both experienced and novice divers a build-up of toxic carbon dioxide can happen very quickly and result in black out or death. As part of a rebreather apparatus, carbon dioxide absorbent materials remove CO2 from gas streams in life safety systems such as those used by the diving industry. Failure to load the correct amount of absorbent material, or use of material which is of insufficient quality, can lead to incidents.

The purpose of this standard is to define the required performance of carbon dioxide absorbent materials for life-support applications. Many life-support apparatus and systems rely on the recirculation of breathing gas and for the gas to safely support life, and any exhaled carbon dioxide needs to be removed. The carbon dioxide absorbent materials responsible for this are usually granules, however, there is no standardization of the quality and performance of these materials.

BS 8618 ensures a known quality, performance and safety of carbon dioxide absorbent materials. It standardizes methods for the assessment of granular or pelleted material for diving and hyperbaric applications against a set of test procedures. The standard is of great value since it covers life safety of military, emergency services, commercial and recreational divers. Although it is not a product standard, it addresses an operational issue for the use of a product.

Anthony Burd, Head of Construction at BSI said: “This standard provides the requirements and test methods for carbon dioxide absorbent materials, and allows users to select the appropriate materials for their intended application. BS 8618 is not just about citing important technical specifications, but also provides best practice guidance that will, better safeguard the lives of divers - this is something BSI and our committee members take very seriously. In this case we are better safeguarding those who work in the military, emergency services, commercial and recreational diving industries. However, it is important to note that BS 8618 does not include materials used in medical anaesthesiology, materials that also generate oxygen, and monolithic pre-formed materials or those embedded within a polymer matrix.”

BS 8618 includes guidance on:

- Activity time in minutes that a carbon dioxide absorbent material can maintain a low effluent carbon dioxide level

- What constitutes a granule/granular/pelleted material

- Friability or propensity of the carbon dioxide absorbent material to form dust and tests to ascertain them

- Volatility or water content of carbon dioxide absorbent material and levels tests to ascertain them

- Guidance on marking of external packaging for carbon dioxide absorbent material - to identify manufacturer, type of material, expiry date, health and safety warnings, storage conditions; as a few examples

BS 8618 was developed using a collaborative consensus-based approach, with input from experts across industry, government, academia and more. Some of the organizations involved in its development include: British Safety Industry Federation, the Health and Safety Executive and the Ministry of Defence.

- Log in to post comments