The Northeast Diving Equipment Group based in the U.S. state of New Jersey is an organization that allows the average sport diver to try hardhat diving. They have been around since 1993 but really started in 1987.

Contributed by

Dave Sutton, an experienced commercial diver, was manager of Lakeland Divers, a dive shop in New Jersey. He purchased a Mark V hardhat rig and started offering a series of recreational hardhat courses. These courses were to familiarize divers with the gear. There was no formal certification.

A number of Sutton’s students, including Fred Barthes, John Melnick and Jim Boyd, purchased the surface supply gear and formed the Northeast Diving Equipment Group (NEDEG). Barthes is the remaining co-founder of this very active group.

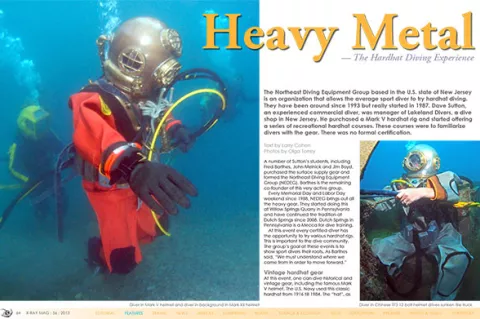

Every Memorial Day and Labor Day weekend since 1988, NEDEG brings out all the heavy gear. They started doing this at Willow Springs Quarry in Pennsylvania and have continued the tradition at Dutch Springs since 2008. Dutch Springs in Pennsylvania is a Mecca for dive training.

At this event every certified diver has the opportunity to try various hardhat rigs. This is important to the dive community. The group’s goal at these events is to show sport divers their roots. As Barthes said, “We must understand where we came from in order to move forward.”

Vintage hardhat gear

At this event, one can dive historical and vintage gear, including the famous Mark V helmet. The U.S. Navy used this classic hardhat from 1916 till 1984. The “hat”, as it is called, saw its heyday during World War II. More Mark V rigs were manufactured and in use during that time.

Divers can also dive Russian and Chinese hardhats, along with a Custom “Scarponi” Helmet. All of these are based on the Mark V design. Vince Scarponi ordered a modified Mark V helmet in 2009. It has a commercial secondary exhaust valve and mounting blocks on the bonnet. The faceplates are oversized and made of Lexan.

These helmets are used with a constant volume suit. The rig has a breastplate to which the helmet is attached. The air flows through the helmet and suit. Barthes said, “It is like diving inside your BC.”

Gas is supplied from the surface by an umbilical. The gas free-flows into the helmet via a diver-controlled valve and exits through a constant exhaust. This creates a large volume of gas in the suit and means one needs to add an enormous amount of weight. This makes the suit hard to work in.

Two to three tenders are needed to dress the diver, and it takes up to half an hour to get the person in the water. The diver and suit will weigh around 400 pounds. If the diver falls over, it takes at least four people to help raise him or her up.

Modern hardhat gear

Divers can also try a variety of modern gear including a Kirby Morgan Superlite stainless steel 37, Aquadyne AH2, band masks and the Desco Pot hat. This equipment is still used by commercial divers.

The Desco Pot hat is used for hazmat work. The Pot hat and the Aquadyne AH2 are hardhats, but are much smaller than the older Mark V. Less weight is needed, and a diver could be dressed in five minutes or less with the help of one tender. They still use a free-flow gas supply from the surface and could be used with a constant volume suit with a breastplate or yoke.

With a yoke system, the helmet is screwed onto the yoke and held in place with a crotch strap. These helmets could also be used with a neck dam. With this system, the helmet seals onto the diver’s neck, and the gas flows only in the helmet, not in the suit.

Neck dams are the way Kirby Morgan Superlite helmets are attached. When diving a Superlite, the gas is still surface supplied from an umbilical, but the hat has a demand regulator, just like open circuit scuba.

Instead of a constant free-flow, the regulator only delivers gas when the diver inhales. This uses less gas than a free-flow system and requires less weight.

A band mask looks like the front of a Superlite, but instead of a helmet, the back is neoprene. A redundant gas supply is always recommended. When diving a neck dam rig, a redundant gas supply is necessary.

All systems have redundant air supplies, and line pull signals are discussed in case the communication system goes down.

A unique experience

Diving a hardhat is a very different experience from scuba diving. Donning the heavy gear will make putting on scuba equipment seem like skinny-dipping. Neutral buoyancy is not the goal. With weighted boots you want to walk along on the bottom.

Since many of the helmets are attached to your suit, when you turn your head the helmet does not turn. Instead, you end up looking out a small side window. This feels very strange at first, but after a few minutes you get used to it. The next thing is the communication system.

It is very strange to hear the tender on the surface talking to you. At first, you start to wonder if you are narked and hearing voices. What is even stranger is the fact that you can talk back, and the tender responds. At least you know you are not hearing voices.

Education and awareness

At present, the NEDEG’s goal is to educate the public about surface supply diving today and in the past. They do presentations in schools, museums, dive clubs and even to the U.S. Coast Guard. They hold exhibits at the New Jersey Ocean Wreck Divers Flea Market, beach clean-ups and local fairs.

The group is involved with setting up a permanent exhibit at the New Jersey Maritime Museum in Beach Heaven, New Jersey. This exciting project will be called the “Evolution of Diving”. Vintage and historical dive gear will be on display, along with the newest technology including rebreathers. ■

For more information send an email to fpbarthes@yahoo.com

Published in

- Log in to post comments