Dying coral reefs saved by automation

Researchers using robotics to grow new corals.

Healthy coral reefs provide food and a home to about 25% of all the world’s marine creatures, sustain an estimated 6 million fishermen, provide coastal protection by reducing the impact of waves and support local tourist economies. But corals worldwide are under threat. Mass bleaching is rapidly threatening the world’s coral reefs, with an estimated 50% already lost and 90% projected by mid-century.

However, hope is far from lost. Dr. Taryn Foster, a research associate at the California Academy of Sciences, has come up with a revolutionary plan to reverse the decline. Foster and her team have established Coral Maker, a collaboration between the California Academy of Sciences and Autodesk.

Automated production

Working across three continents and four time zones, their objective is to use coral science and manufacturing technology to produce one million live corals annually by automating the coral production process. "Coral reef restoration programs often operate with limited means," said Shubham Goel, the Coral Maker team lead and a senior engineer manager at Autodesk. "We care deeply about simplicity and efficiency in every aspect of the design process."

Coral restoration programs have existed for years but have faced a significant issue: Scaling their efforts. Restoration methods such as coral gardening are done manually and are very time consuming. Slow coral growth rates pose another problem. "To get from a 10 centimetre fragment to an adult colony can take anywhere from 3 to 10 years, depending on which species you're talking about," said Foster.

Science and technology

To address the scaling issue, the Coral Maker team is combining science, manufacturing technology and traditional manufacturing techniques. The design begins with a premade coral skeleton, a dome-shaped base composed of stone material similar to corals' natural calcium carbonate skeletons. To mass-produce the skeleton, Coral Maker is using dry cast moulding, a traditional masonry manufacturing technique that could potentially produce 4,000 stone coral skeletons daily.

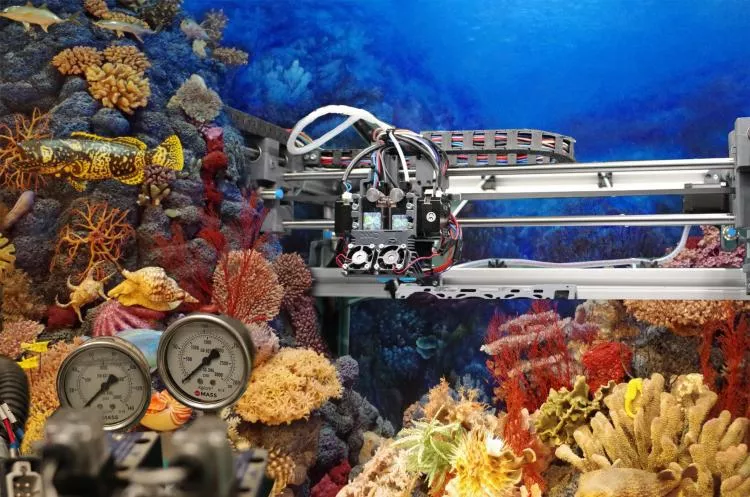

A robotic arm then inserts seed plugs with live coral fragments into the skeleton, a process previously done by hand. Vision sensors and machine learning are utilized to pinpoint the position of the dome and seed plugs and install the seeds in the right place.

Once deployed to the ocean, the new corals will re-coat the skeleton’s surface, ultimately creating an adult-size coral colony. With a premade skeleton, the coral doesn't need to calcify its skeleton from scratch, reducing the time to reach adult size from three to 10 years to about six to 18 months.

Deploying prototypes

By the end of 2020, Coral Maker is intending to deploy prototypes with real coral fragments into the ocean, collect data and make improvements to the design. Though the pandemic has shut down the prototyping facility, researchers are using home 3D printers to keep the plan on track.

"We know that corals did exist at higher latitudes, as in further away from the tropics, in the last interglacial period. So they have, they have the ability to move," Foster said. The problem is that it takes five to 10 thousand years to move on their own. If we could set up a reef at a meaningful scale at a high latitude, then maybe we could create little pockets of survivors," she added.

While Coral Maker and scientists work to regrow the ocean's coral, anyone can take steps to change their ecological footprint on a daily basis. If strides are made to end climate change, Coral Maker’s survivors will have a better chance of enduring to the next generation. "If people have awareness of climate change—if they're willing to change their own behaviour, but also advocate for change—then I think that's what's going to have the biggest impact," said Foster.